The TCC8303.I tread color code inspection

is designed as an online device for detecting and controlling the colors applied to a rubber profile.

The system is based on computer vision with the use of a camera system and lights.

The number of cameras depends on the profile’s width and the required measurement accuracy.

The system can detect the position and correctness of the color marking as well as spilled ink or missing color.

For a concept that includes regulation abilities, the system works in a closed loop and automatically regulates the position of the color marking on the rubber profile.

Technical parameters:

- Profile width of up to 450 mm

- The option to adjust color markings ±200 mm from the profile’s center

- Width precision < ±200 µm (3 sigma)

- Precision for the detection of color marking positions < ±200 µm (3 sigma)

- Recording frequency of 20–30 frames per second

Suitable for:

- tread

Versions:

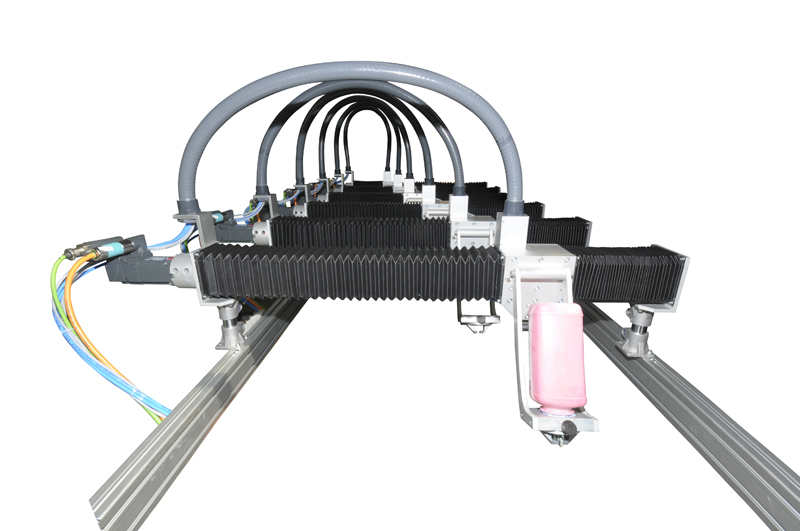

- Camera box (without a positioning mechanism)

- Automated solution (with a positioning mechanism)

Options:

- Profile width measurement

- Calibration unit

- Combining with a continuous scale

Benefits:

- Contact-free measurement of profile geometry

- Online measuring system for quality control

- For the automated version, the system can work without positioning intervention by the operator